Challenge - Create - Collaboration

Challenge

Create

Collaboration

We always try hard to find out problems and solve out for requestments to fit customers absolute satisfaction

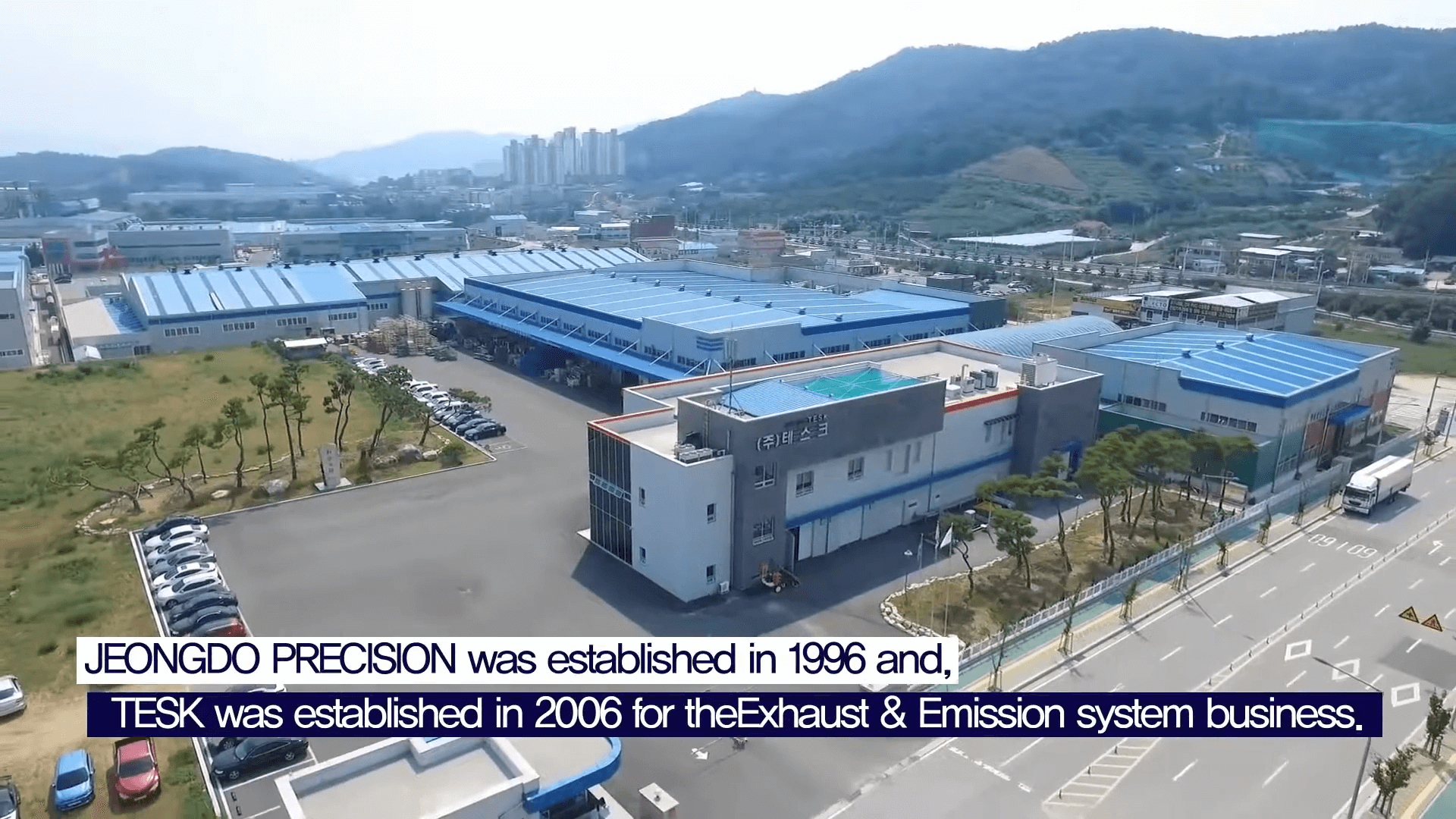

History of the factory

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout.

1996

~

2006

2007

~

2013

2014

~

2018

2018

We continue our journey with you

Some Of Our Trusted Clients

Factory Flow

We always try hard to find our problems and solve out for requirements to fit customers absolute satisfaction.

Coil Loading

Stage of quality inspection, diameter, classification and dismantling of coils.

Tube Mill

Welding process, forming tubes form coils, adjusting the sixe, shapes, sizes, lengths for pipes, sorting and packing tubes

Bending & Forming

The process of expanding, squeezing and forming pipes according to standard diameters.

Welding

Using different types of welding rebots to assemble and weld pipes according to standard models.

Packing & Delivery

When the process is complete, the tube is packed and the product is delivered to the customer.

Certifications & Awards

Certificate of Registration

“Standards are named in the format "JIS X 0208:1997", where X denotes area division, followed by four digits designating the area (five digits for ISO-corresponding standards), and four final digits designating the revision year.”

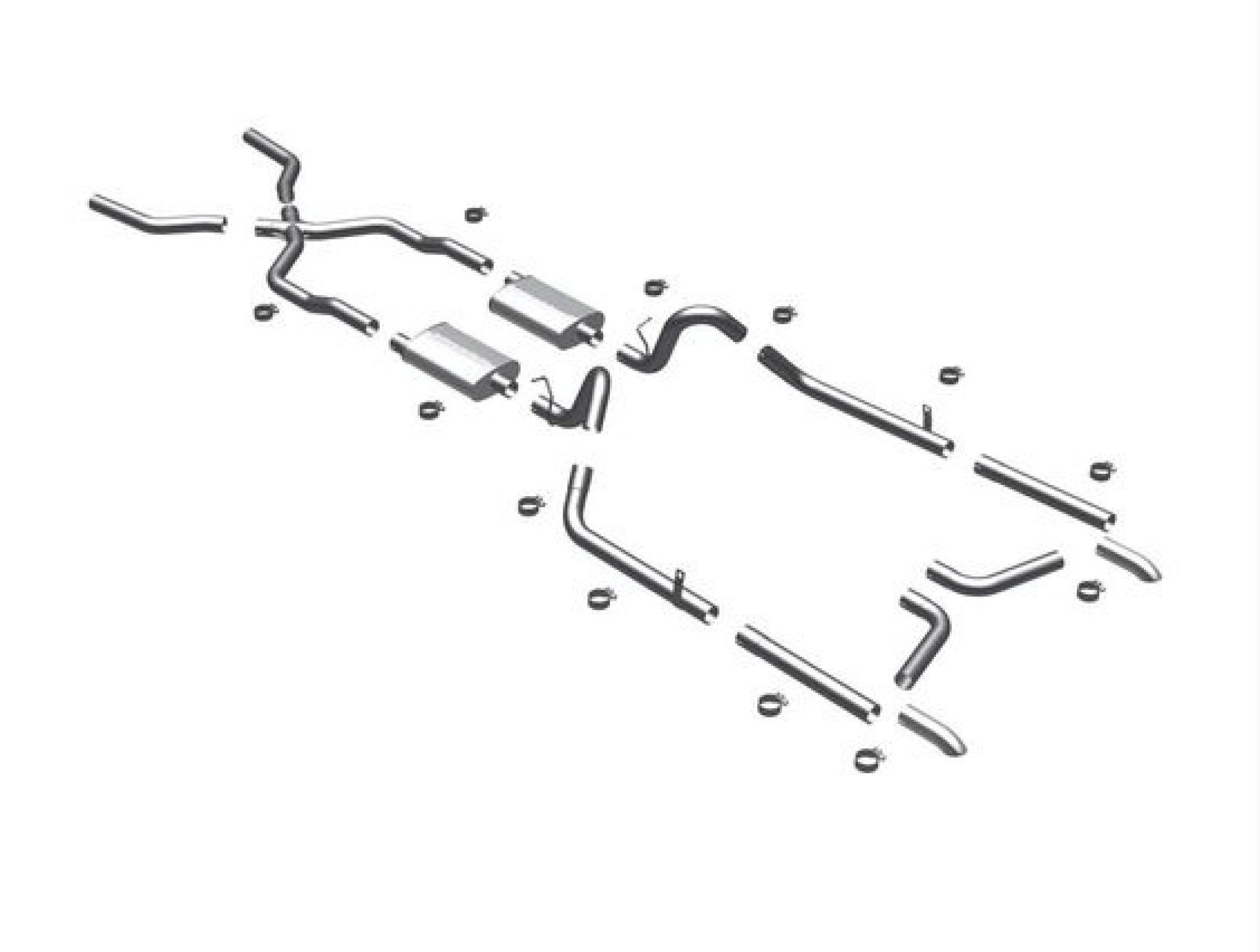

Our Products

We always try hard to find our problems and solve out for requirements to fit customers absolute satisfaction.

Tube

Automotive

Commercial Parts

Furniture

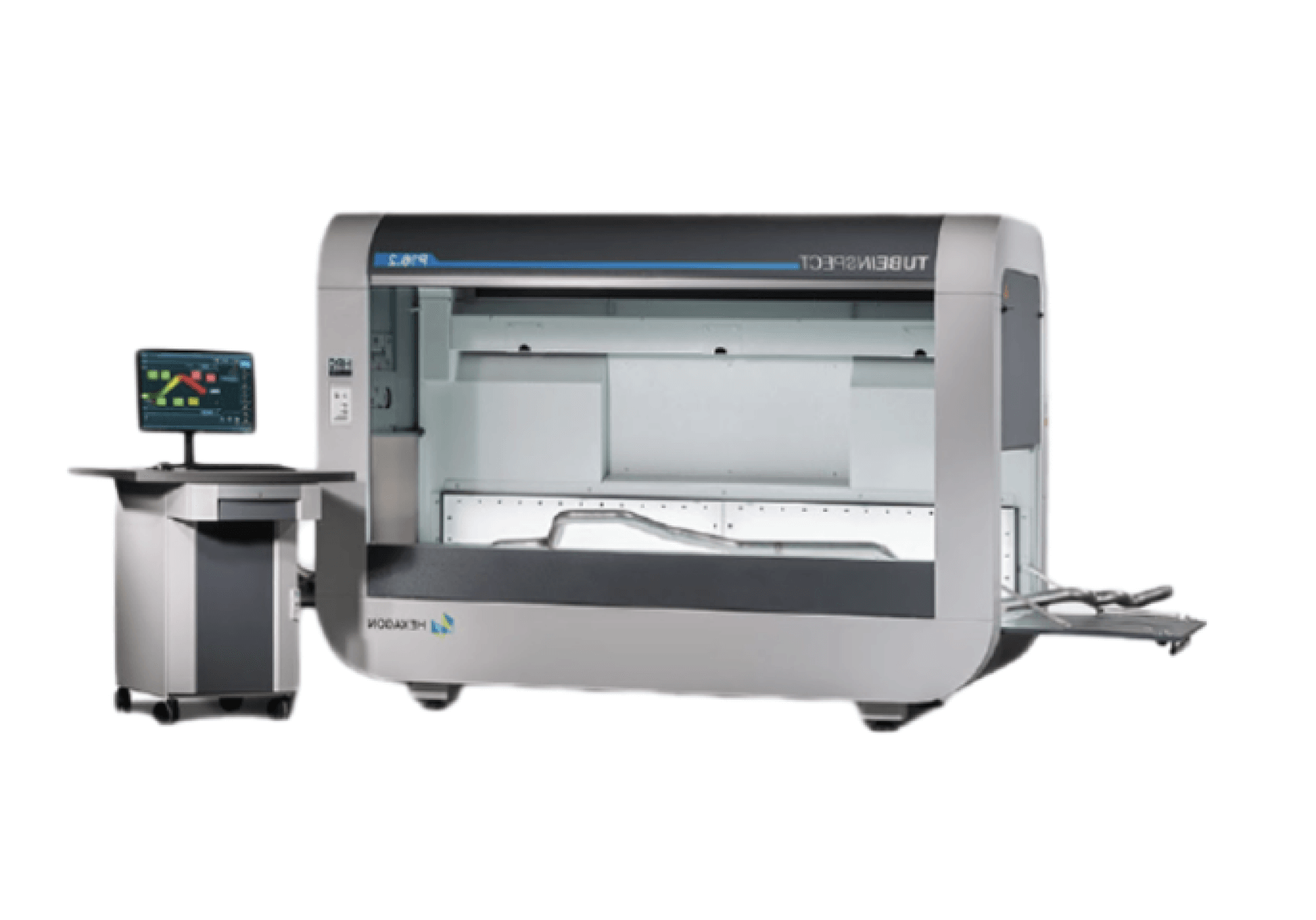

Quality Control

Safety, economy, and compliance with regulations are essential for our production process. Our quality control process takes into account many variables.

material

pipe quality checking

Location

We are growing global competitiveness throughout the world.